Page 1 of 1

Building a 1915 engine

Posted: Sat Nov 20, 2010 8:03 pm

by Old-Towd

Ed Buggy Buddy was over a while back helping me do a tune up on my Baja Freja when he notices that the pulley was moving in and out a little to much, we figured you should be able to check the end play at the pulley because the engine was still in the car. O ya 32 thousand play, this movement is supposed to be limited to between .003" - .005" with a wear limit of .006", time to pull the engine. With my Fiberglass Buggy Wrecker still sitting in limbo I didn't want two cars down in my garage so I installed a 1600 engine out of my donor car. That I only ran a few time in the Tow'd it wasn't the best engine but it would able me to move the Baja in and out of the garage, funny thing that engine has been on about 7 runs including Utah in the Baja, runs great just a little under powered on grades . So back to the build I had a few cases sitting on the shelf, a little more disassemble and I was off to Rimco for some machine work. A day later and a call from Rimco ( like a totalled car to much to repair ) my case needed major thrust bearing work and with a sloppy snout it would need a sand seal installed. Ok 2nd case pull apart what looked like a unmolested Type 3 engine with standard crank off to Rimco with my second case. O ya a call from Rimco second case has cracks by three and four and the 10mm case studs would not let me open the case to 94's, man I been saving these cases for years I have one left a Type one with a super lose rod and a piece of case broken off below the flywheel at the bottom where you use a nut and bolt, I think some one was using one of those skid plates that bolt to the bottom of the engine and hit something real hard. I'll disassemble the 3rd and hopefully I'll be off to Rimco on Monday, the standard crank from the Type 3 is at Top Line, Jon is having it counter weighted. Anyone have any dual relief cases. I'll post any progress. Having fun Jay

Building a 1915 engine

Posted: Sat Nov 20, 2010 9:56 pm

by Grumpy One

Jay,

Sounds like you are having fun - cleaning out the garage.

Joe

Building a 1915 engine

Posted: Mon Dec 20, 2010 1:51 am

by Old-Towd

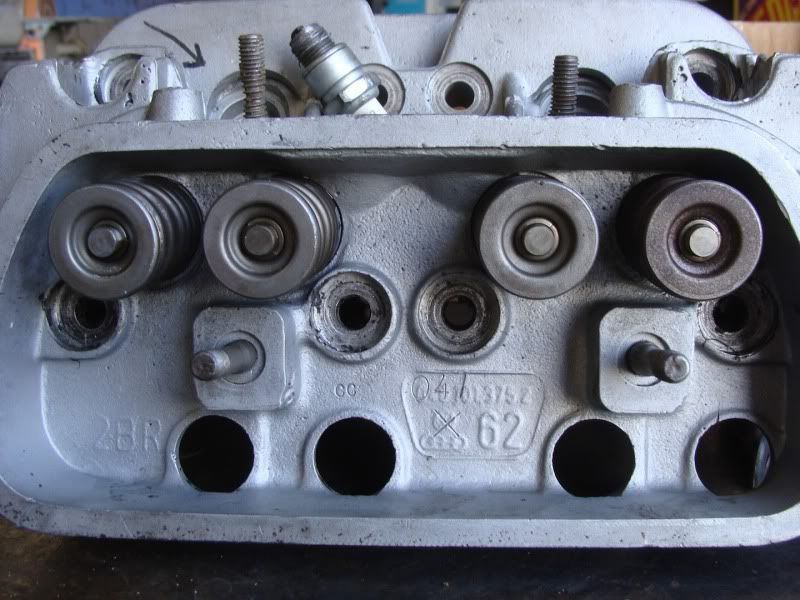

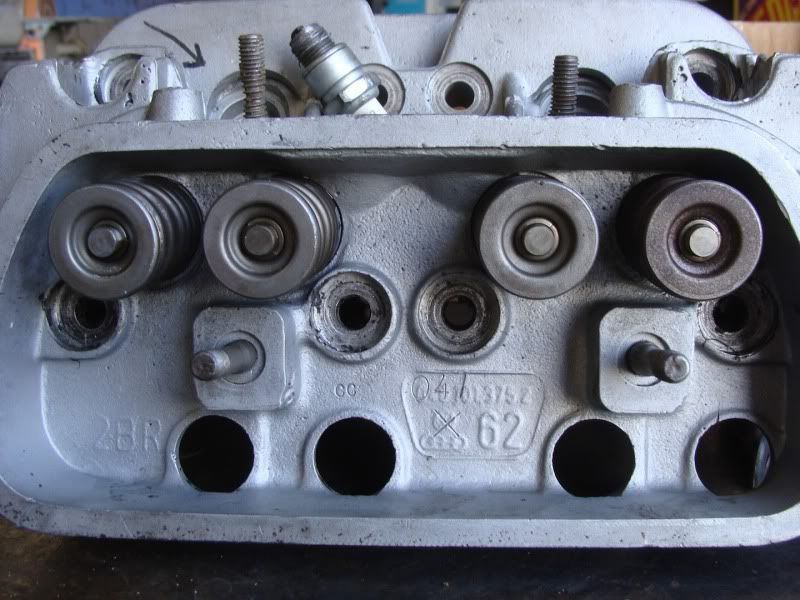

Too cool I got my 3rd case back ready to go , and I was

down at Top Line Jon's shop and found a set of German converted 041

heads. There was a cross threaded spark plug , so off to Clyde Berg for

inserts in all four and a Valve refresh. I'll be running Engle W-100

cam .

Building a 1915 engine

Posted: Mon Dec 20, 2010 3:44 am

by jsturtlebuggy

Jay,

What are German converted 041 heads? They were made in Brazil and had 39mm intakes and 32mm exhuast valves. The fix to make them perform was to replace the exhaust valves and seats to a larger size of 35mm. Also opening up the intake seat for a 40mm valve.

Building a 1915 engine

Posted: Mon Dec 20, 2010 4:19 am

by Old-Towd

Hi Joseph Buddy, maybe I worded it wrong . There German heads that some one changed to 041 valves at least that's what I thought, what do you think?

Building a 1915 engine

Posted: Mon Dec 20, 2010 5:08 pm

by jsturtlebuggy

OK now I understand Jay.

Someone out there decided to make there own converted heads.

Do you know what size valve combination they have?

Wow what happen to that manifold stud?

With that 2BR in the head casting it is a head that came from Brazil.

Building a 1915 engine

Posted: Tue Dec 21, 2010 5:05 am

by Old-Towd

O man Joseph not German Heads , so if they have 2BR there made in Brazil whats this world coming to. The valves look like 40x32 , thanks for your help Joseph.

Building a 1915 engine

Posted: Fri Dec 24, 2010 8:52 pm

by MELFOL

Jay: Years back SoCal imports had someone cheaply putting larger valves & seats in Brazilian heads. Those may be a set. Not sure. Though bigger valves and seats I don't think the ports had any work on those. Whereas on a real 041 head the ports were about 15% larger to work with the bigger valves. Something else to look for: On some I've seen the intake valves were so close to the edge of the chamber they were shrouded (couldn't breathe well on that side) by the edge of the combustion chamber. When the valve opens to get efficiency out of a larger valve it has to be able to flow air in every direction. If the intake valve is too close to the edge the combustion chamber can be opened a little more to unshroud it for better flow on that side. But then you will have to CC both sides alike so they match in volume. If no other work but larger valves has been done you might consider some port work and making sure the intake valves aren't shrouded to get the most out of them. Otherwise they are just a big valve with small valve head restrictions.